Before your departure, a mechanical check is necessary. It’s not uncommon to go on a great group hike and often come back with black hands. Especially if you are one of the most resourceful of the group. Faced with a fait accompli, you realize that a simple mechanical detail can lead to an escalating embarrassment.

We have all experienced an event like this. One of the snowmobiles of the group stops on the edge of the trail. We all join it and then the same question always comes up. “What’s there? The answer always starts like this: “Well it looks like …!” We are then on all fours in the wilderness to perform bush mechanics. With the comments of each one, the means of the edge and the imploration of a celestial god, the breakdown service of fortune is not always possible. The return with the snowmobile at the end of a rope is sometimes the inevitable solution.

In the vast majority of cases, a simple mechanical check will be enough to avoid these breakdowns. I will take you on a tour of a snowmobile and you will understand that some maneuvers are simply visual and very simple.

Before your departure, a mechanical check is necessary – A little tour first

It is best to start your mount and give it a quick test run for a few minutes. At this stage, be aware of noises and vibrations. Take advantage of the fact that the engine is running to turn on all the heating accessories, lights, 12-volt outlet, etc. Don’t forget your reverse gear and its horn. Once these steps are completed, bring the snowmobile into the garage and turn off the engine.

The caterpillar and its components

Start by raising the rear of the snowmobile. Inspect the track to see if there are any studs missing or if there is any splitting. Small pieces of rope sticking out of the track are not a concern. For a better visual appearance, you can burn them with a small butane torch. Probe your track wheels. Push on the track to clear the wheel and rotate it, if it is groaning, the ball bearing on it needs to be replaced. Pay attention to the surface of the wheel. If there is a flat or deep dent, it should be replaced.

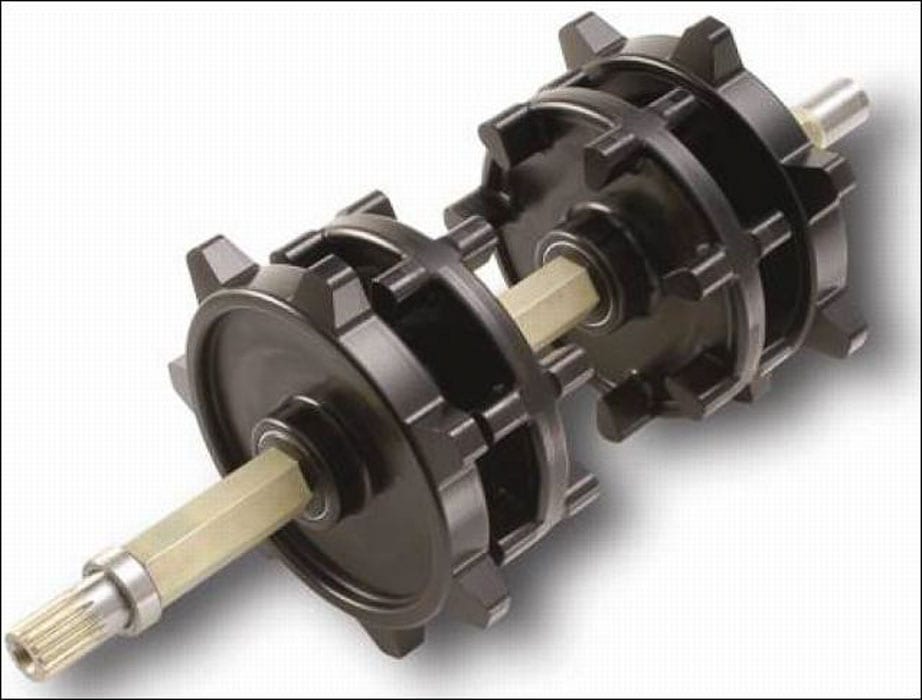

The sprocket

The sprocket is the large gear at the front of the track that transmits power from the engine to the track. Check for missing pieces of teeth. If so, replacing it will be the solution. However, this replacement task is very complex.

Rear suspension

Look closely at the springs to see if they are broken or just in the right place. Shock absorbers: Look at the condition of the shock absorber rod. Oil or rust is not a good sign. Some shocks are repairable, which is cheaper than replacing the entire shock. Simply remove it from the snowmobile and go to a mechanic shop that will be able to refurbish it.

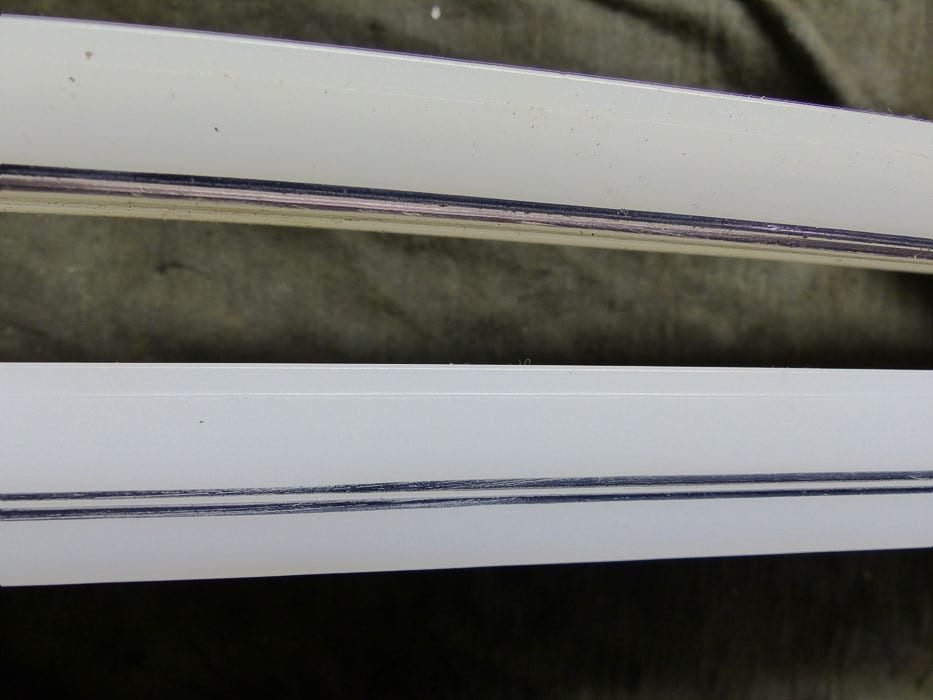

Track slides

On the sides of the track slides, notice the line that is drawn on them. It indicates the limit of acceptable wear. Once the slides are worn at this line, they should be replaced. The slide support requires special attention. It is possible that it cracks, deforms or that the assembly rivets come loose.

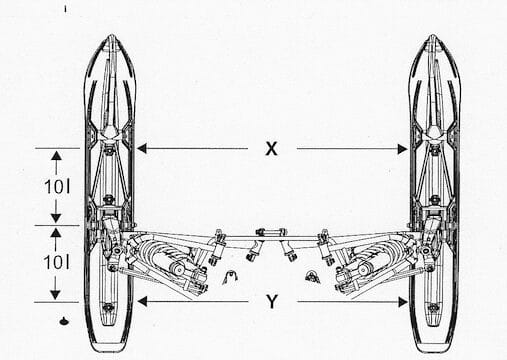

Tensioning the track

With the rear of the snowmobile raised, apply a downward tension of approximately 10 to 16 pounds. Measure the clearance between the track and the rails. The desired measurement is 0.5 to 1.25 inches on center of the track. At the same time, measure the alignment from left to right of the track. If it is out of specification, unscrew the rear track wheel axle a few turns and adjust it with the stop screws.

The Skis

Skis are one of the good reasons why a ride is enjoyable or not. Poorly adjusted skis can cause a lot of swaying or loss of control of the snowmobile. You will find yourself tense at the handlebars in order to keep the beast on the trail. Observe the general condition of the skis, wear or deformation. With the handlebars straight, measure the alignment of the skis. Align if necessary. Lift the front of the snowmobile and inspect the rails. Usually they have carbide inserts. If the carbide is gone, replace them. The carbide is primarily responsible for the efficiency of the steering on ice or hard packed snow.

Balls and rods

With the front of the snowmobile raised, grasp the front of the ski and move it from front to back. Observe the ball joints and bushings on the suspension arms. Do the same with the steering rods. A little play is acceptable, otherwise replace the part. Lubricate the ball joints and tie rods with motorcycle chain lube or equivalent.

Under the hood

Cable

Lift the snowmobile’s hood to gain access to the engine. Inspect the throttle and brake cables. From the levers, operate them. If there is a sticky feeling, look for the cause. In the case of a snowmobile with a 2-stroke engine, do not neglect the oil injection pump. A frayed cable or a cable with a worn or cracked sheath will definitely be a problem.

Hoses and pipes

Locate the fuel, oil and coolant hoses. Check them for leaks. If so, an emergency repair is needed. You may notice an oily build-up in the bottom of the engine compartment. This may be normal. In the case of a 2-stroke or carbureted engine, vent pipes from the carburetors or exhaust valves are routed to this area. These pipes allow oily vapors to escape and collect there.

The exhaust

Exhaust parts often suffer from life. Breaks, leaks, corrosion, missing springs, etc. It is better to check their condition a few times during the winter season.

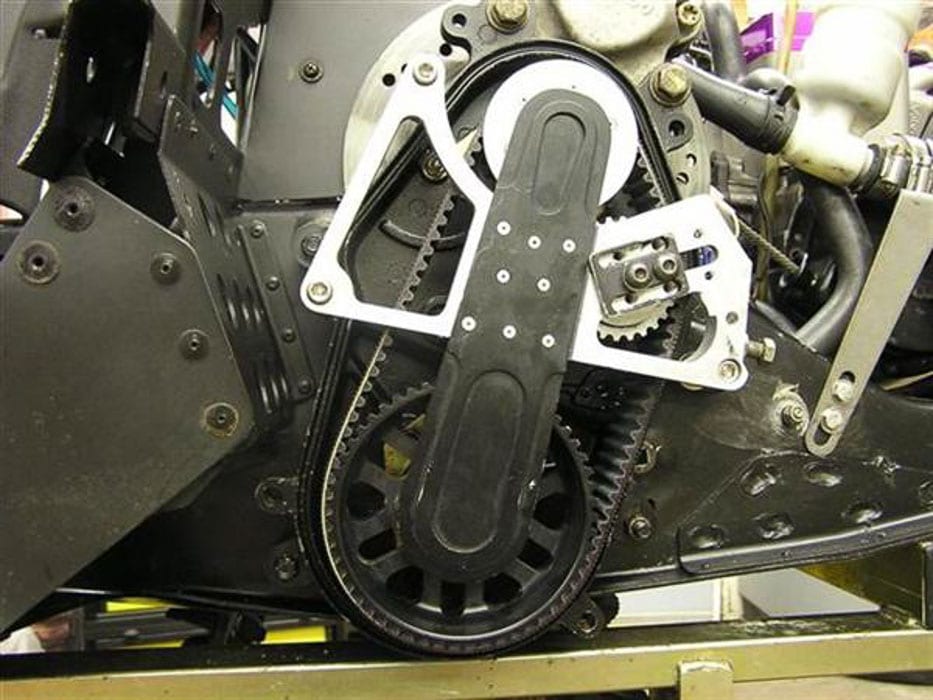

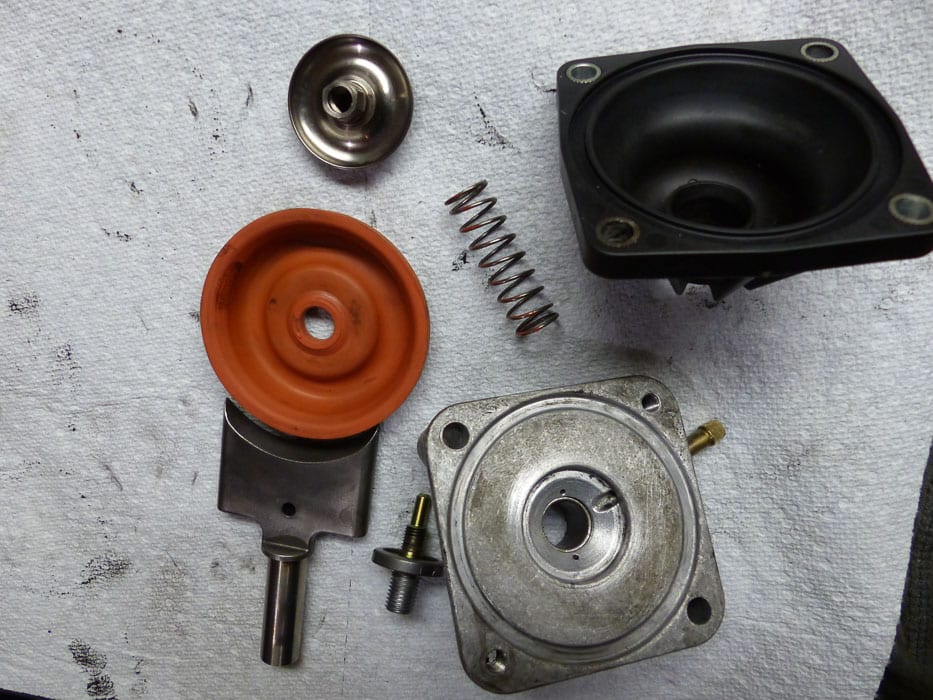

CVT System

Your CVT system can be one of the biggest sources of trouble on the trail. If it’s making noises or vibrating, you’re right to suspect that something is wrong. Start by checking to see if the belt is even, without fraying or warping. At the beginning of the season, cleaning the friction surfaces of the clutches with Scotch Brite or fine steel wool will remove any marks left by the belt. As you clean these surfaces, notice if the belt has made any wear notches, especially on the bottom of the primary clutch. Blow out the clutches with compressed air to remove any belt dust build-up. Although some adjustments can be made to the alignment of the clutches and their opening, a job of this caliber requires equipment and expertise. If in doubt, have your CVT checked at a specialized shop.

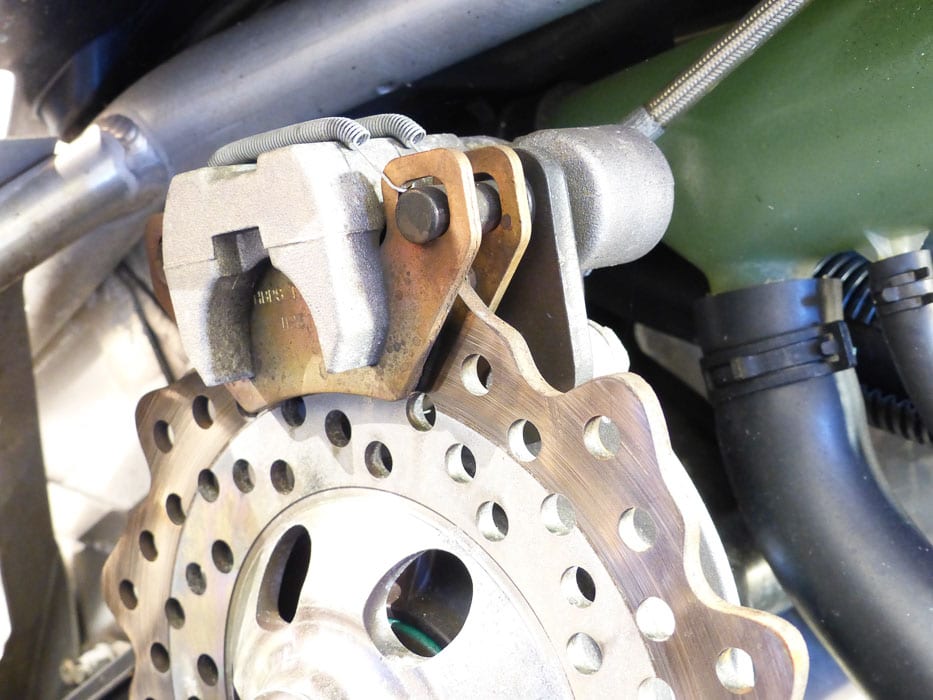

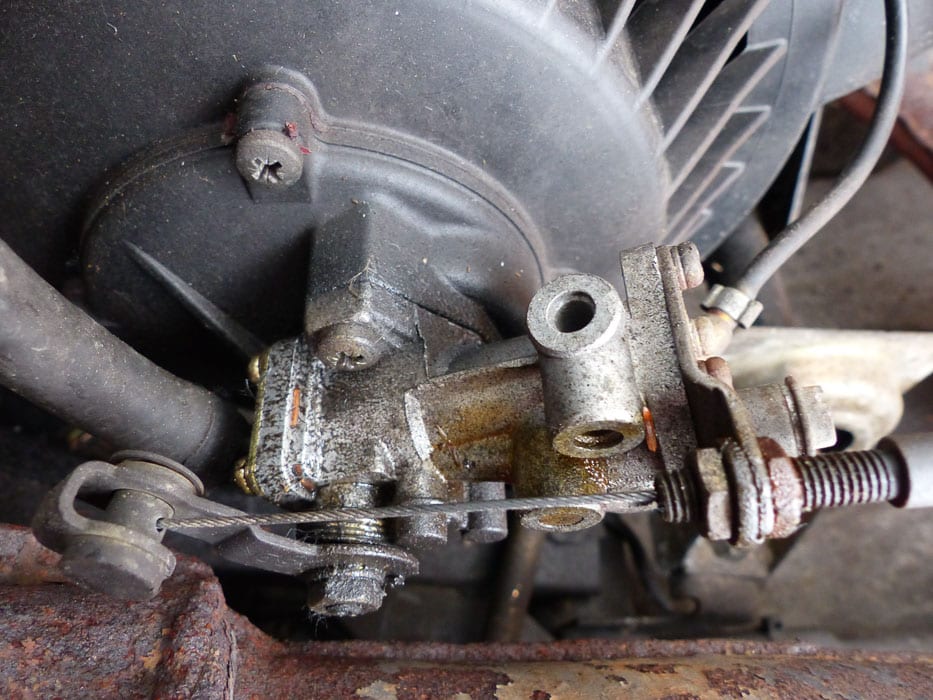

Brake system

The braking system is very simple. There is only one brake disc. Check to see if the brake pads are the right thickness and that the caliper engages properly and, most importantly, if it releases completely when the brake is released. A good look should be taken at the brake discs and surrounding components. Sometimes overheating the disc can melt nearby parts.

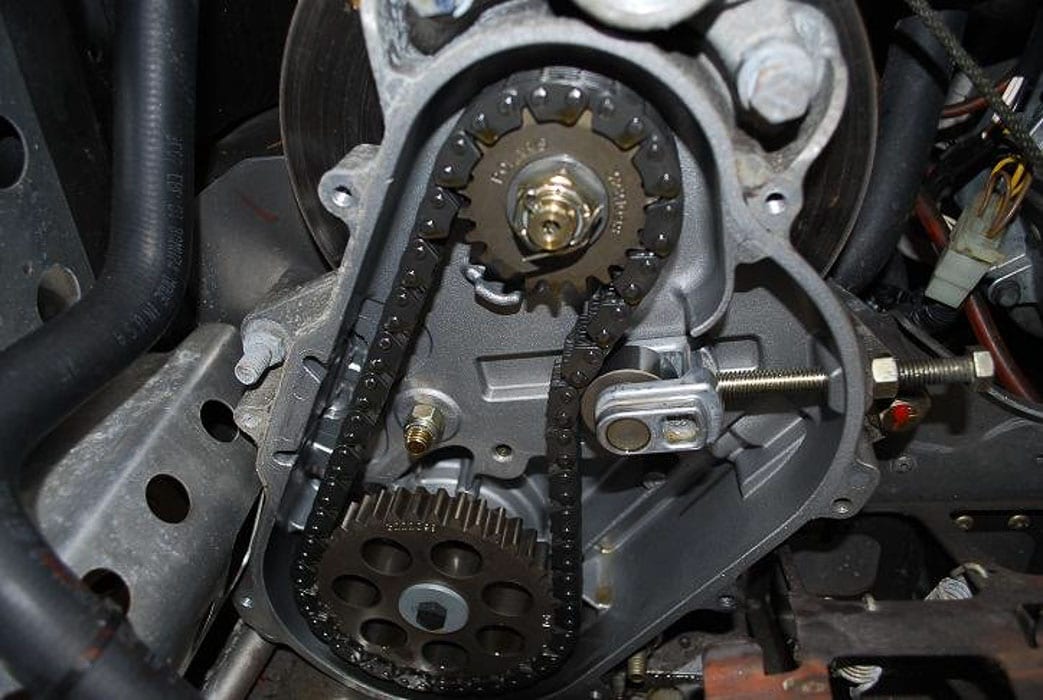

The transfer case

The transfer case is the link between the secondary clutch shaft and the track sprocket. Its work is extremely powerful. In most cases, it is made up of sprockets, gears and a chain that is immersed in oil. Check the oil level in your gearbox. If the level is low, look for a leak. I always suggest changing this oil every season. If you are lucky, your snowmobile will have a drain plug, otherwise, removing the transfer case cover will be necessary to change the oil. Check the used oil or the magnets in the drain plug. If you find any metal particles, it’s a sign that a more thorough check is needed. If not, close it and adjust the oil level in the transfer case.

Adjust the housing chain. Simply loosen the lock nut several turns, release the sealing washer and hand tighten the adjustment screw. Push the sealing washer back into place and tighten the lock nut.

Some snowmobiles are equipped with a toothed belt transfer case. A visual inspection of its condition will suffice.

Greasing

Lubrication points are very important to the long life of your snowmobile. Simple, but often overlooked, most lubrication points are located in the rear suspension linkage, at the track sprocket ball bearing and sometimes in the front suspension as well.

Fuel supply

In the past, carburetors were used and required very complex maintenance. Since the advent of fuel injection, there is almost no need to service the fuel supply. If something is wrong, chances are your on-board module will tell you via the malfunction indicator on the instrument cluster.

The engine

To begin with, there are 2-stroke and 4-stroke engines.

Let’s start with the 4 stroke engines. An oil and filter change should be done before starting the season. During the season, watch out not to exceed the manufacturer’s suggested maintenance intervals. The very compact design of the snowmobiles makes the maneuvering sometimes very complex depending on the model.

Then, with 2-stroke engines, some extra care is required.

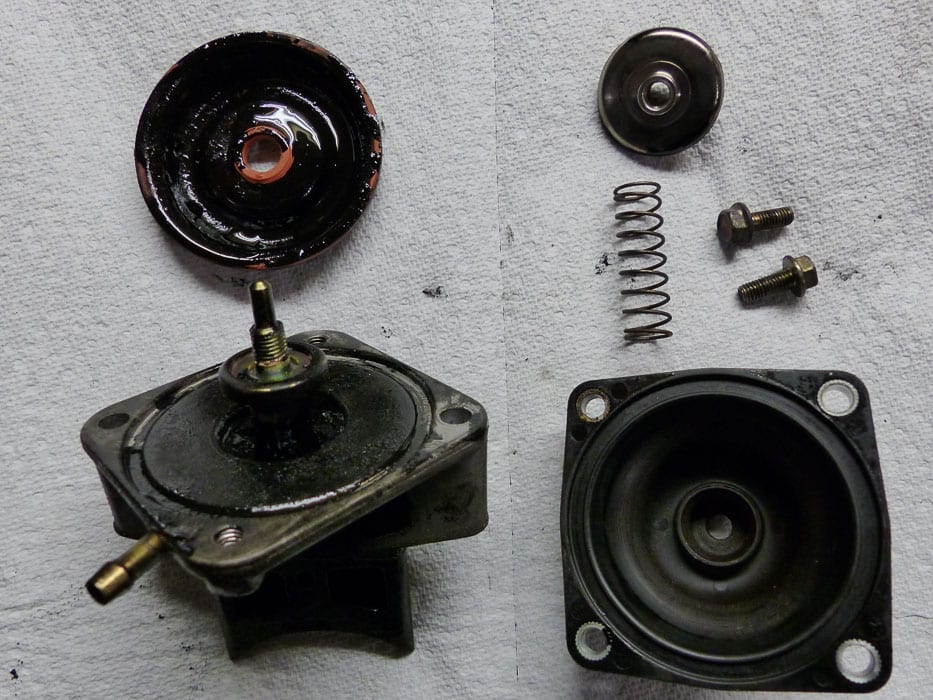

Pay close attention to the oil injection pump. On some models, the pump is driven by a plastic shaft. Over time, it wears out and breaks. Then, it’s the end for your engine. I suggest taking a look at it once a year. Make sure the pump mounting screws are not loose and at the same time confirm that the calibration marks are still aligned properly.

Exhaust valve

Most 2-stroke snowmobiles are equipped with exhaust valves. You may recognize them as “power valve” or “rave valve”. I suggest a good cleaning of these valves every 1 500km to 2 000km. Fouling is often very fast. Get the valve seals and remove them from the engine. Clean them thoroughly. Inspect and reinstall the valves to the engine with new seals. Be careful not to install the valve on the wrong side.

Spark plugs

Spark plugs are a very simple solution: you get new ones at the beginning of each season and spare ones in the snowmobile. Take this opportunity to inspect the spark plug wires and their connections.

The battery

If your snowmobile has one, recharge it at the beginning of the season. Go to a mechanic shop to have it checked. If it passes the test, you’re usually good to go for the season. If in doubt, come back with a new battery.

Manual starter

Pull the starter rope as far as it will go. Inspect the condition of the rope. Perform a few tests to confirm that the starter engages with each pull.

Fluids

Check fluid levels: coolant, fuel injection oil (2-cycle engine), engine oil (4-cycle engine), etc. Adjust if necessary.

A clean snowmobile is nice. It’s not just nice, but safe. A clean snowmobile makes it much easier to see fluid leaks or broken parts. A little cleaning then!

Of course, here I am explaining an annual pre-season inspection, but there is always the possibility to take a 15 minutes every 2 or 3 rides which will be very beneficial to avoid breakdowns. A visual inspection of the track, the track wheels, the suspension, the belt, the fluid level and a simple tour of the snowmobile can let you detect many anomalies and avoid going on a one-way trip.

Although the technology on recent snowmobiles has evolved in terms of fuel economy and reliability, the snowmobile is still a vehicle that is expected to perform beyond its limits. The purpose of each model influences its preparation and maintenance intervals. Adjust your inspection rounds to your ability. For the rest, there is always your trusted mechanic shop.