New Snowmobile Technologies 2017 – With the presentation of the new 2017 models, it is also an opportunity for the manufacturers to present the technological advances that are at the heart of the development of the sport of snowmobiling. In addition to improving the performance, comfort and capabilities of vehicles, these technologies also contribute to making our sport more environmentally friendly, as well as more accessible to new enthusiasts.

When analyzing the new products for 2017, we can see that it is a great year of innovations for several manufacturers. Two new engines arrive in the industry and these will be used on a large scale by 3 manufacturers. Once again, we have the privilege of witnessing the arrival of a new platform that is likely to set new standards in the industry in terms of mass centralization. Naturally, suspension is always at the center of manufacturers’ evolutions, as well as vehicle weight reduction and drive systems. The 2017 vintage shows once again that we are privileged to be passionate about a vehicle whose pace of evolution is one of the fastest in the motorsports industry, year after year.

Engines

Presenting a major evolution in its direct fuel injection technology, Ski-Doo has chosen to develop a new engine with the Rotax 850 E-TEC. By increasing the displacement by 49cc, the mill produces 10 more horsepower for a total of 165 hp. In addition to the extra power, the engineers actively worked on the engine’s pick-up times by increasing the response speed by 30%. This is made possible by a new electronic module that processes twice as much data per second, more precise coil injectors, as well as the addition of booster injectors that operate at mid and high rpm. One of the major objectives with this new engine is to increase its durability. Several technologies and concepts inspired by diesel and 4-stroke technologies are used in this new engine to add more robustness. A forged crankshaft in two sections, direct oil injection to the crankshaft bearings, more durable piston ring holders, and plasma coating of the cylinders are also part of these new innovations. Despite the increased performance of this new engine, fuel consumption is comparable to the 800R E-TEC while oil consumption is reduced by 40%, compared to the 600HO E-TEC. Having been designed in symbiosis with the 4th generation REV chassis, this new engine is only available in models that benefit from this new platform in the MXZ, Renegade and Summit.

Yamaha designed a new turbo engine from scratch, which is the opposite of the past years when turbo systems were added to existing 4-stroke engines. This is the reason why this engine is not offered in a non-turbo version. Having the advantage of making the costly design of a new engine with Arctic-Cat profitable, this new mill is incorporated into a multitude of models from both manufacturers as soon as it is launched. Known as the Genesys 998T at Yamaha and the 9000 C-TEC4 series at Arctic-Cat, this engine develops more than 180 hp and benefits from a host of new technologies, including the new control module (ECU) created in partnership with Mitsubishi. This is one of the most advanced control modules ever proposed, as it must manage all the components of the engine and the turbo compression system. With an intake manifold for each cylinder, it goes a long way to eliminating the delay that has historically characterized this technology. Combined with the air bypass system that reroutes excess air from the turbo into the supercharger intake, the response is instantaneous. The latter creates a more constant pressure in the turbo system, avoiding variations, so that it is always ready to respond to the rider’s accelerations. Naturally, Yamaha’s engineers designed the engine with durability and reliability in mind. The majority of the parts of the turbocharging system, as well as the internal engine parts, were designed to withstand the enormous pressure and heat generated by the power of the new mill. Yamaha has a tradition of reliability and does not want to compromise on this aspect, even when producing a high performance engine.

Chassis

Ski-Doo is once again innovating in the field of chassis, thus maintaining its leadership. With this in mind, the Valcourt-based manufacturer presents the 4th generation of its REV chassis, which sets a new standard in terms of balance and mass centralization. The balance of weight between left and right is now at the heart of the design thanks to a drivetrain that is custom built for the new platform. In addition to having an almost 50-50 left-right weight distribution, the engine itself is placed 2.2 inches closer to the center than the previous chassis. Ultimately, the goal with this new platform is to offer snowmobiles that are better balanced, narrower and therefore more maneuverable, both on trails and in powder. The new bevelled tunnel also reduces the width of the seat, making the rider feel lighter and more manoeuvrable. To complete this quest for extreme maneuverability, the ergonomics of the vehicle have been designed to facilitate the rider’s movements. This makes it easier to switch from a ride mode to an ultra sport mode thanks to various standard features. The Ergo-Step side panels with stepped design offer three riding positions. In addition, the front of the footboards is completely open and allows you to take the boot out in tight turns. So it’s a new REVolution that BRP engineers are offering for 2017. Upon launch, this chassis is offered in the MXZ, Renegade, as well as the Summit but with some variations for mountain snowmobiles.

Suspensions

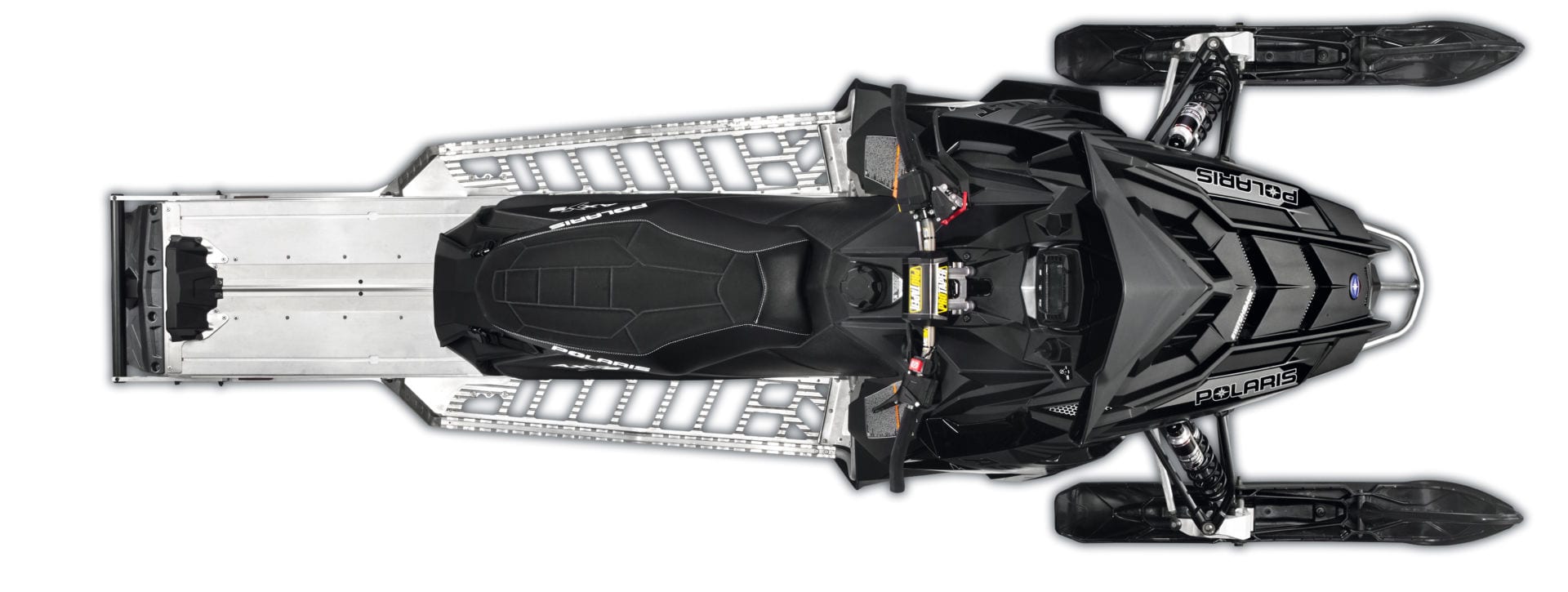

Polaris is introducing the new IGX-144 rear suspension, which is now available on many of its 144-inch tracked snowmobiles, except those powered by the 550F engine. Designed to provide the same agility and balance in powder as the suspension found on the RMK, this suspension also offers significantly improved trail control. Thanks to a new uncoupled suspension geometry and increased travel at the front of the track, the track causes far less tailgating. The new track design is also stiffer than in the past, while being lighter.

Ski-Doo continues the evolution of its front suspension by introducing the RAS 3 for 2017. Similar in design to the RAS 2, this suspension still features outward orientation of the skis when at maximum compression for greater precision. In addition, two important improvements have been made to refine the design.  First of all, the RAS 3 is 0.7 pounds lighter than the previous generation. Also, the travel is increased by 1 inch on the MXZ and Renegade and by 0.8 inch on the Summit. All this in order to get the full potential of the new 4th generation REV platform.

Clutches

With the arrival of a brand new engine with so much steam horsepower, Yamaha engineers needed to make sure they had a new clutch system that could absorb and transmit all that power to the track. The new YSRC drive pulley, designed for the new Genesys 998T engine, does just that. It offers increased durability while being very efficient at all speeds. In addition, this pulley is designed to cool itself very efficiently. ¬†The YSRC driven pulley with reverse ramp was designed to reduce friction, increase efficiency range, and reduce premature wear caused by excess power. In short, Yamaha’s engineers left no stone unturned in order to transmit the full potential of the new engine to the track.

At BRP, the design of a new platform and a new engine was done in parallel with a new driven pulley, the new “pDrive” pulley. The objective is to allow for a more dynamic response of the new 850 E-TEC, while creating a narrower drive train. The main feature of this pulley is the use of frictionless rollers instead of slides. This allows the pulley to respond very quickly and has 30% less rotational inertia than a TRA. This is also made possible by the fact that it is 15% lighter than the TRA with 2.8 pounds less. The pDrive pulley is also maintenance free, with a design that promotes cooling.

New components

Arctic-Cat continues to improve several components of its mountain chassis. With the arrival of the new Mountain Cat model, the American manufacturer also introduces the new “Mountain drive system”. This system positions the sprocket 1.125 inches lower than the manufacturer’s other mountain models. In addition, eight-tooth sprockets are used on snowmobiles equipped with the “Powerclaw” track with a 3-inch profile. This new positioning reduces the angle of attack of the track by 9.7 degrees. The objective of these improvements is to facilitate climbing on snow, while reducing the loss of power by reducing friction.

Standard on the MXZ-X and Renegade X, the new adjustable forward elevation block is a very effective innovation. Being easy to adjust, even while in motion, this module adds four forward adjustments and allows the rider’s position to be adjusted without tools. Based on the principle of a parallelogram, the angle of the steering wheel and its accessories does not change even if the handlebars are moved forward or backward.

For 2017, Polaris decided to change the footboards on its 144-inch track Switchbacks. Snow evacuation was clearly an issue on the older generations, which is no longer the case with the new “Powdertrac” footboards.¬† With over 56% of the surface open, these were designed specifically for backcountry enthusiasts. These new treads are also wider at the front with a flatter angle, which makes maneuvering easier and improves rider comfort.

With the arrival of the new XCR, the Roseau-based manufacturer also introduces the PRT braking system. Designed for increased efficiency and durability, this new system is based on three key elements. First of all, the new brake disc is larger and therefore disperses heat better while being more durable. The same goes for the “type 81” brake pads which are more heat tolerant and therefore last longer.¬† Finally, a side air intake constantly cools the entire system for greater efficiency and durability. The result is efficient braking at all times, even when the ambient temperature is higher.

Conclusion

Clearly, this article does not present all the 2017 innovations from the 4 manufacturers. Rather, the objective is to bring your attention to the highlights of the new technologies that have particularly caught our attention. Each manufacturer presents all of their innovations on their website and you can easily access them via the web. However, I wanted to highlight the innovations that had a real impact on my tests and on my experience, which is the ultimate goal in my opinion.