Checks to be carried out by yourself before the first planking! For as long as I can remember, since I’ve been a snowmobile fanatic, I’ve been waiting for the imminent arrival of the first snowfalls, especially in the middle of the summer heat wave. Sometimes, to refresh my mind, I look at my snowmobile pictures from the past years to whet my appetite for what the next winter season will bring.

However, when fall arrives, it is imperative to start preparing our snowmobile (if you are using the same mount as the previous year). We recommend a mechanical check-up at a dealer, especially on the engine and clutch system. However, there are some checks that are easy to perform and will also give you a clear idea of what repairs you will decide to hand over to your trusted mechanic. This way, you won’t be left to the last minute and be added to a waiting list when many enthusiasts wake up to the arrival of the first snowflakes. Forethought is the key to starting the season on the right foot.

Maintenance and verification points:

1-Check the spark plugs and don’t be stingy, replace them if they show signs of age.

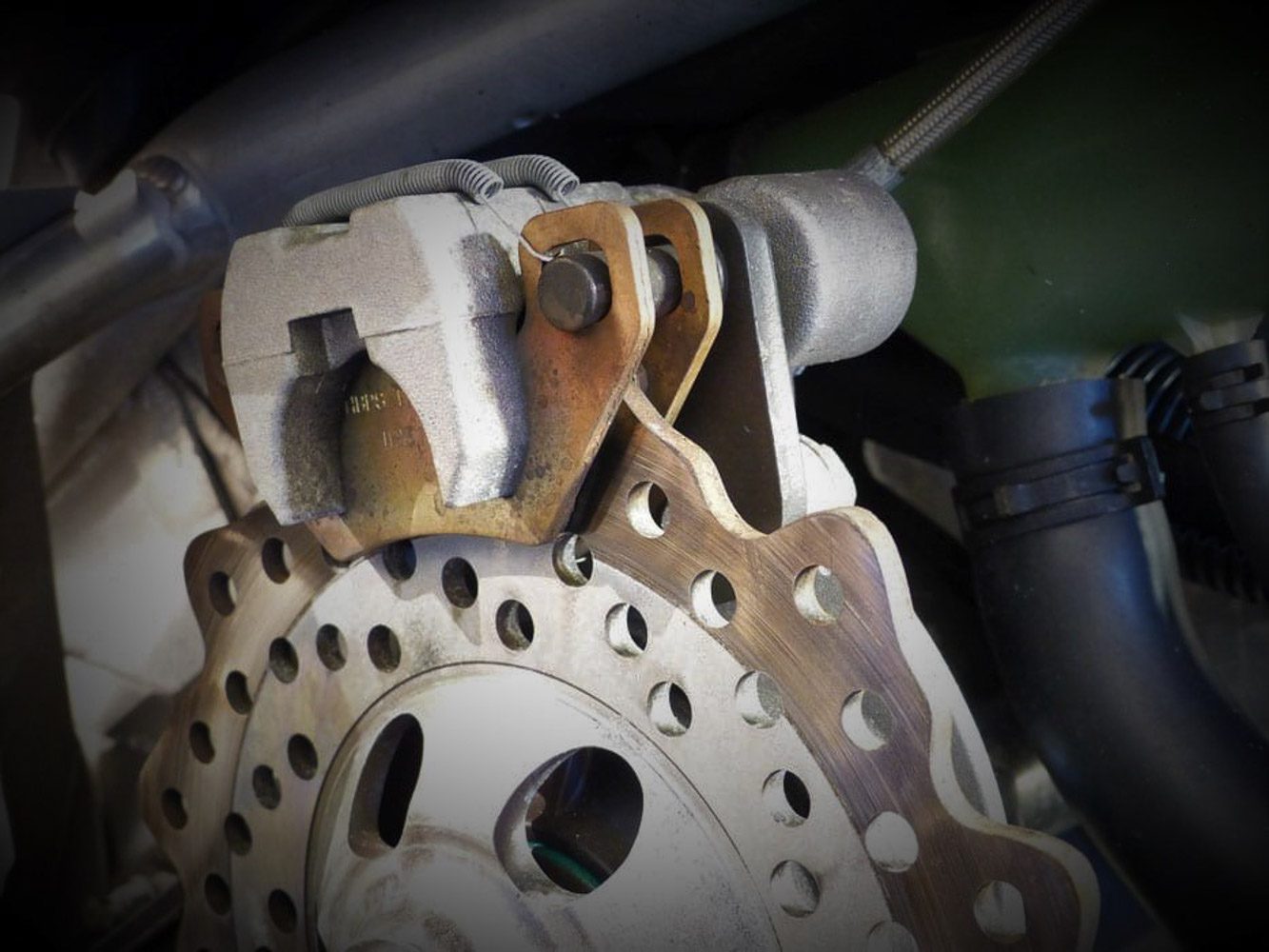

2-Inspect the brakes. Check the thickness of the bands to ensure safe braking. If necessary, replace them.

3-Do the headlights, tail lights and brake light work? Safety first, right? Oh, sure, you probably don’t want to read any safety tips, but have you ever followed a snowmobile at night with a burnt-out tail light? It’s annoying. So make sure your snowmobile’s tail light is working, and while you’re at it, make sure the brake light, headlight and kill switch are working too.

4-Change of chain case fluid is important to maintain the reliability of the transmission. Oil viscosity degrades with heat and many BTUs are generated in a snowmobile chain case. Snowmobile transmission oil may also have leaked or water in it. It will be milky white in color because of a bad seal, so changing the fluid may allow you to discover these problems and fix the cause. Most snowmobiles have a drain plug at the bottom of the housing. After filling with fresh oil, adjust the chain tension to the manufacturer’s specifications.

5-Check the clutch to make sure the area around the belt is not iced over creating a loss of traction. Remove the drive belt and lightly rub the two clutch pulleys with sandpaper. Do not use steel wool as this will polish the metal. Run your hand in a straight line, in and out, between the outer edge and the center of the pulley. Once there is an even pattern of scratches on each side, wash them off with warm water. If you leave the fine metal dust on the clutches, it will seep into the rollers and bushings and accelerate wear on these parts.

6-And don’t forget to check the belt and its condition. Layer separation, missing lugs and frayed edges are all reasons to replace a snowmobile drive belt. Before reinstalling the belt from the previous maintenance step, inspect it carefully for damage. Belts may look fine, but they could be the cause of reduced peak engine speed or generally anemic response when you press the throttle. Always have a spare for the trail and the tools to change it on the fly.

7-Check the exhaust for signs of leakage (blackening around the seals). -Make sure the springs holding the connection points have tension and are not rusted.

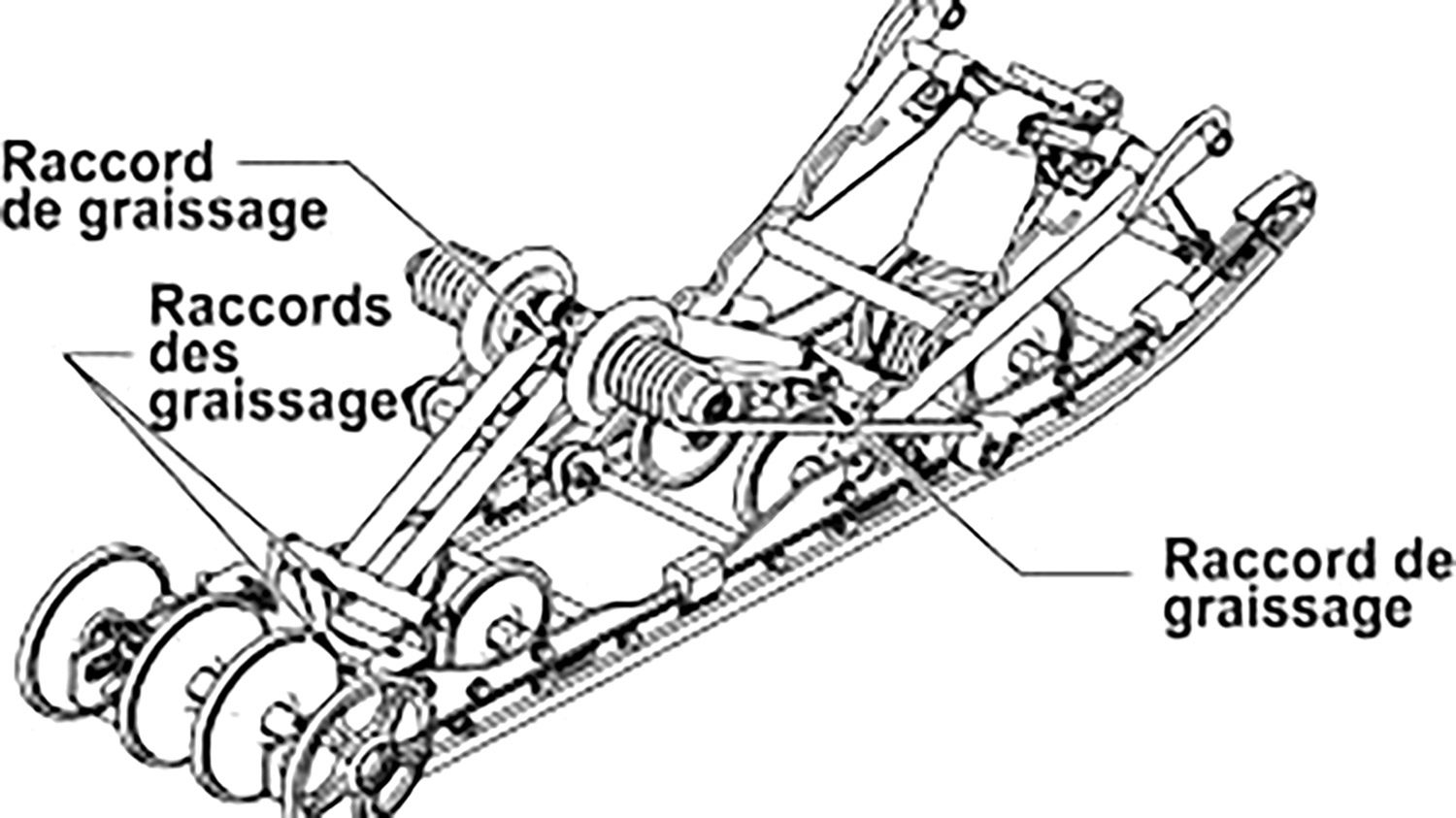

8-Grease/lubricate all suspension points and moving components as recommended in the owner’s manual. Remember to use a low temperature grease.

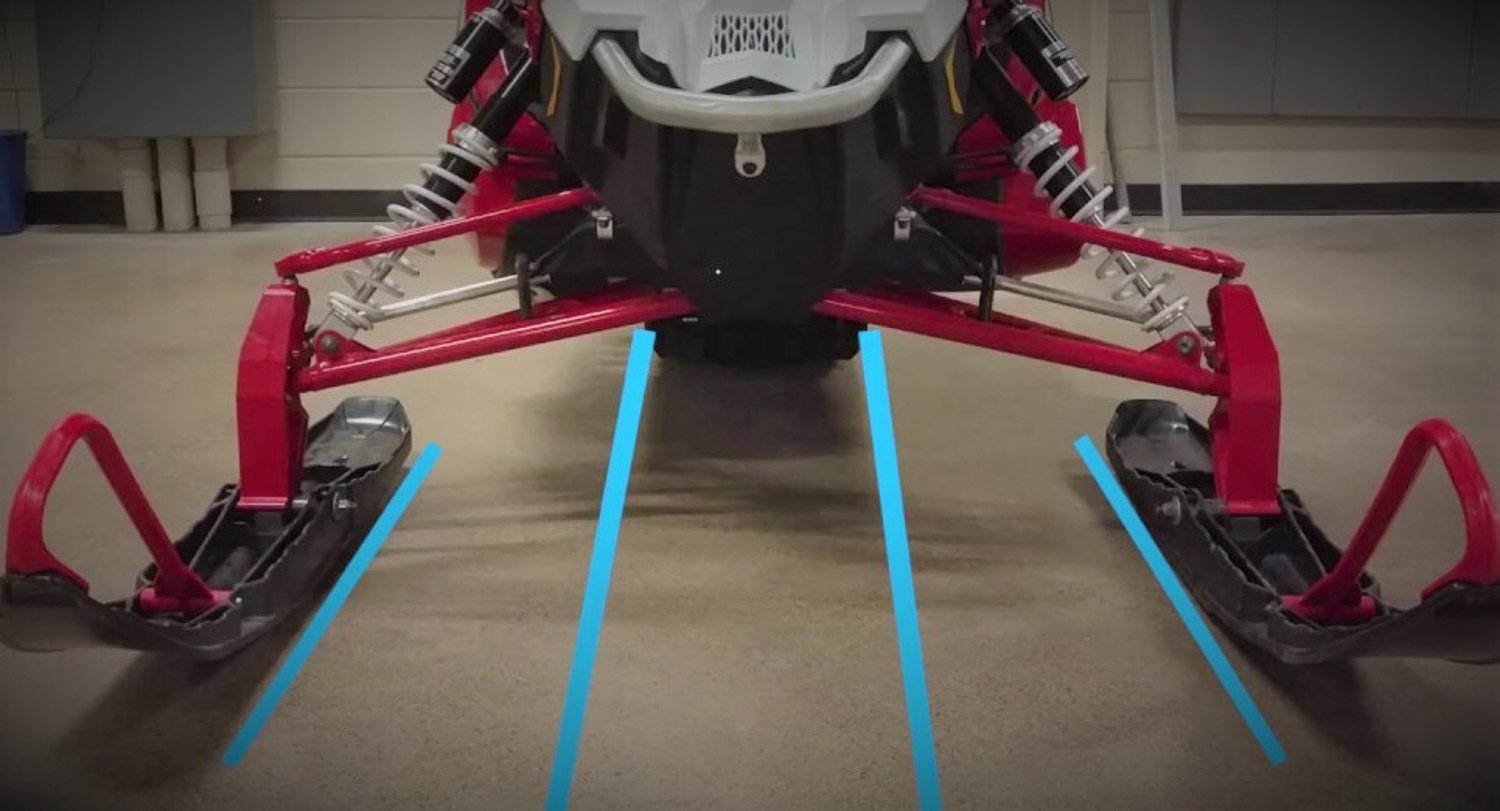

9-Make sure that the front skis and steering are aligned and that there is no unnecessary play in the steering.

10-Check the carbides on the wear bars under the skis. Replace them if they are worn or almost gone. This is very important for safety and handling. They can wear out quite quickly if you drive or cross a lot of snowy roads.

11-Check fluid levels and top off according to the owner’s manual.

12-Inspect the plastic guides on which the track slides. These are wearing out and need to be replaced. There is usually a wear indicator line on them.

13-Check the wheels and bearings for damage.

Go through all possible visible bolts. Seriously, these things endure a lot of vibration and they can loosen up over time. Be careful and check everything you can.

14- Lift your snowmobile and check for signs of excessive deterioration of your track. Take the opportunity to adjust its alignment and tension.

Checks to be carried out by yourself before the first planking! –In summary

if you review all the points listed above, you will have a sense of confidence in your snowmobile and peace of mind. When in doubt, don’t hesitate to go to your trusted dealer for a more thorough inspection.