The gasoline your snowmobile consumes is essential to its proper operation. The method used by manufacturers to fuel the engine has changed dramatically over the past decade. The evolution has gone from carburetors to multiple technologies of standard and direct injection systems. It is important to remember that the fuel selected at the pump can also have a major impact on the fueling and operation of the engine.

The carburetor

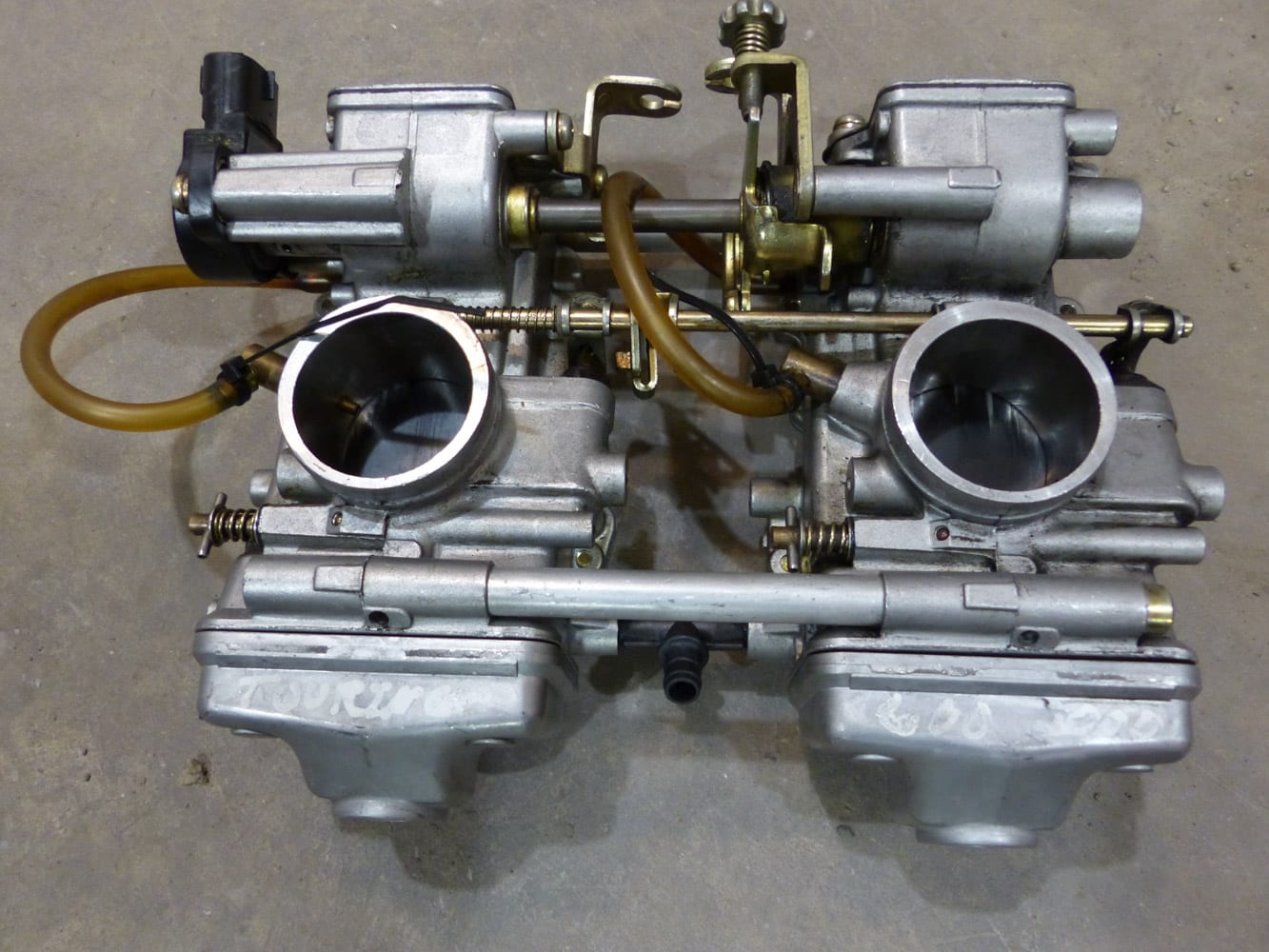

Snowmobiles of past generations fed their engines with one or more carburetors. Sometimes one carburetor fed more than one cylinder and in other configurations, there was one carburetor per cylinder. The manufacturers used carburetors usually made by either Mikuni, Keihin or Hitachi. The adjustment of a carburetor requires a certain mastery of the subject, especially if the engine is equipped with several of them. The jet nozzles, the needle, the needle closing level must be adjusted in order to reach an ideal stoichiometric mixture for the engine, and this, in all its operating ranges. Quite a challenge!

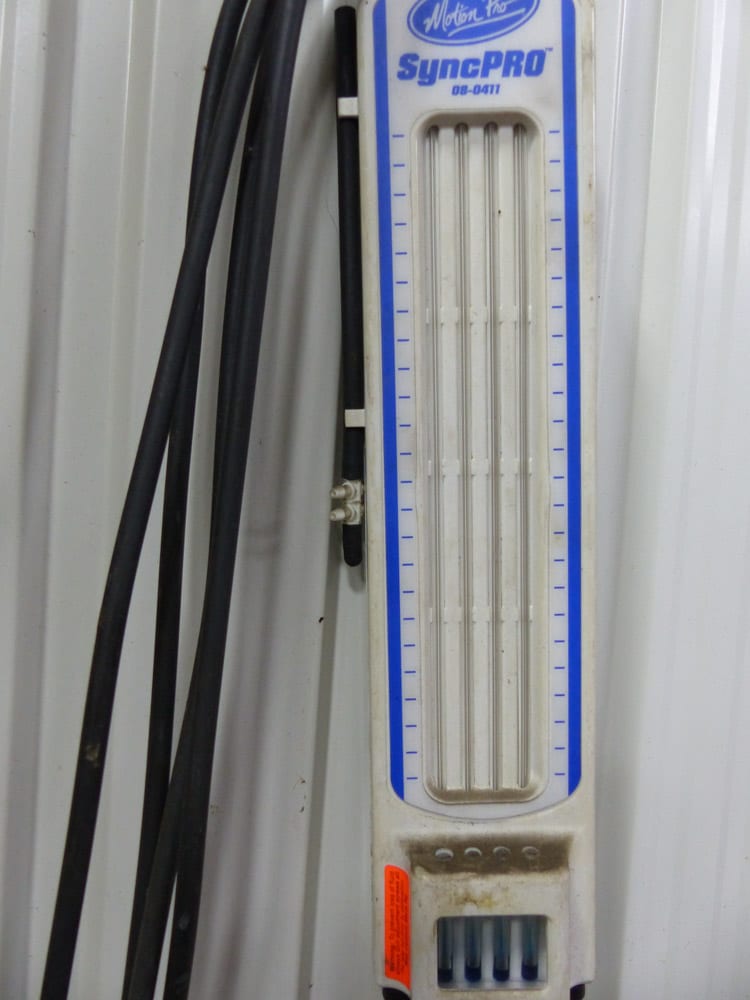

If the snowmobile is equipped with multiple carburetors, balancing between them is essential. Without this calibration, the contribution of each cylinder of the engine will be unequal, which will cause erratic operation. This calibration is done with a tool that measures the engine vacuum downstream of the carburetors. To do this, we adjust the opening of the carburetors until a perfect balance is obtained.

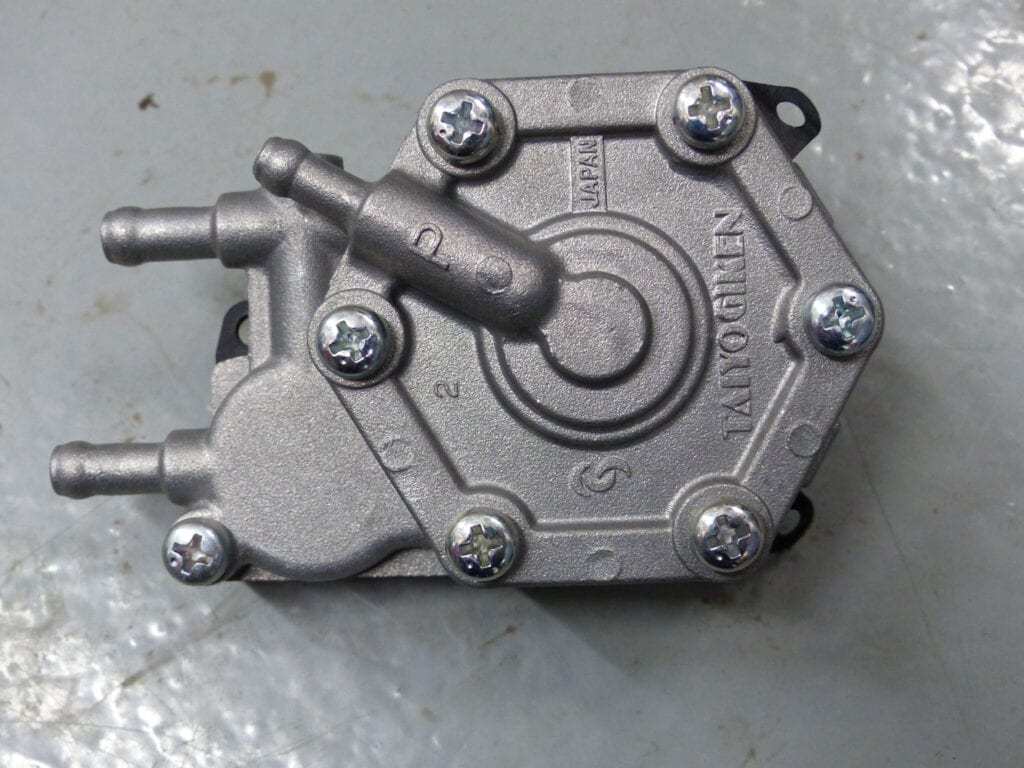

Carburetors must be fed by a fuel pump. Fuel is delivered to the carburetor by a diaphragm pump. The diaphragm is activated by the pulsating vacuum of the engine. The back and forth movement of the diaphragm then pumps the gasoline to the carburetor. The resulting pressure is only a few PSI.

Fuel injection

Fuel injection is currently the most awarded technology by snowmobile manufacturers. It allows a much more precise control of the stoichiometric mixture. The level of pollutants is therefore much more respectable and at the same time it results in surprising savings on fuel consumption.

What a fuel injection system should include

In order for an injection supply to be possible, the engine must be equipped with an electronic management module. This module applies a preset map which, depending on the data from certain sensors, adjusts the volume of fuel to be injected. This action can be calculated up to 8,000 times per second. The sensors responsible for the calculation are the throttle opening sensor, the air intake vacuum sensor, the atmospheric pressure sensor, the air temperature sensor and the engine coolant sensor.

In some cases, sensors measure the exhaust gases and provide feedback to the engine’s electronic management module so that it can see the result of its action. Although a two-stroke and four-stroke engine are very different, this information is necessary for the injection of both technologies. We must not forget the injector itself. It is simply a sprayer of fine droplets of gasoline. It has several orifices, which provides a finer and more even spray.

Regular injection

The regular injection system of a four-stroke snowmobile engine is very similar to that of an automobile. The carburetor is replaced by a throttle body. This part is very similar to a carburetor with the lower section removed. The injector is often housed in its upper part or, with some manufacturers, it is inserted directly into the intake manifold.

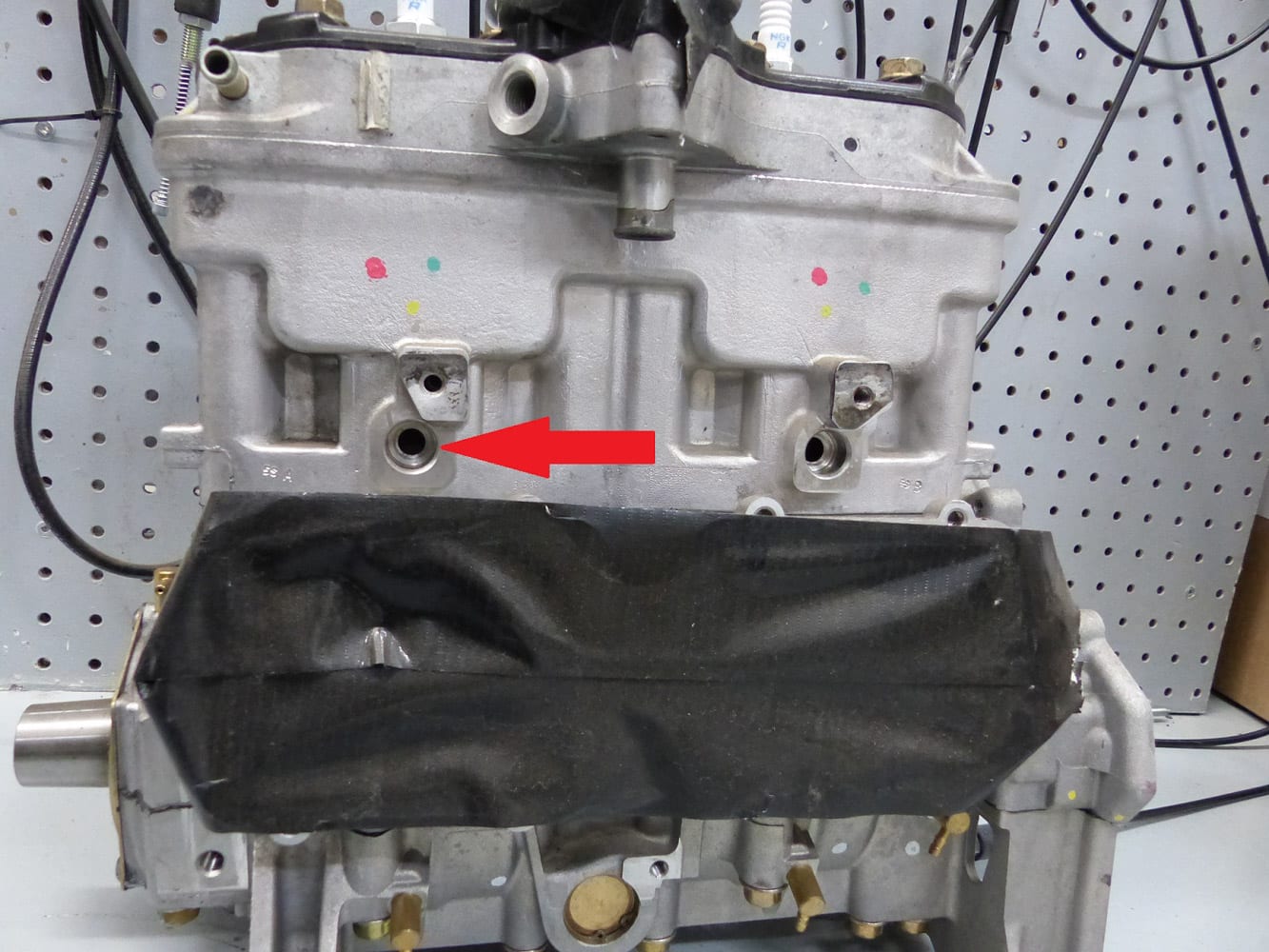

For the two-stroke engine, the injector is directly attached to the base of the engine. Other snowmobile manufacturers will run one injector in the base of the engine and another in the intake window for the same cylinder, which optimizes even vaporization. This results in two injectors per cylinder. In order to meet the new environmental standards, these snowmobiles are now equipped with a more efficient lubrication system to reduce hydrocarbon emissions via the exhaust.

However, the fuel pressure required to operate an injector is much higher than that of a carburetor. The diaphragm pumps used to feed carburetors do not have the power to raise the fuel pressure to the 45 PSI required to operate an injector. An electric pump with a high pressure filter is used to accomplish this task.

Direct injection

Direct injection does not yet seem to be making its way into four-stroke snowmobiles. On the other hand, in the design of two-stroke snowmobiles, the presence of direct injection is very real. Many technological advances have been made. First of all, let’s remember that the conventional two-stroke engine has the unfortunate tendency, during the exhaust process, to have a portion of the air-fuel mixture go straight through the exhaust and into the muffler.

So a lot of hydrocarbons end up in the environment. Since the oil is carried through the engine by the gasoline, the polluting effect is even greater. Suddenly, a totally new concept has emerged. Why put oil everywhere? The principle of lubrication at specific points appeared. This resulted in a remarkable 30% reduction in the consumption of injection oil. As for fuel economy, it is just as impressive. With this specific point lubrication, the oil is no longer transported through the entire engine. The option of positioning the injector directly on top of the cylinder head is now possible. The fuel injector takes center stage precisely in the heart of the cylinder head. It injects fuel directly onto the engine piston.

Now it’s time to explain the feat of significant pollutant reduction.

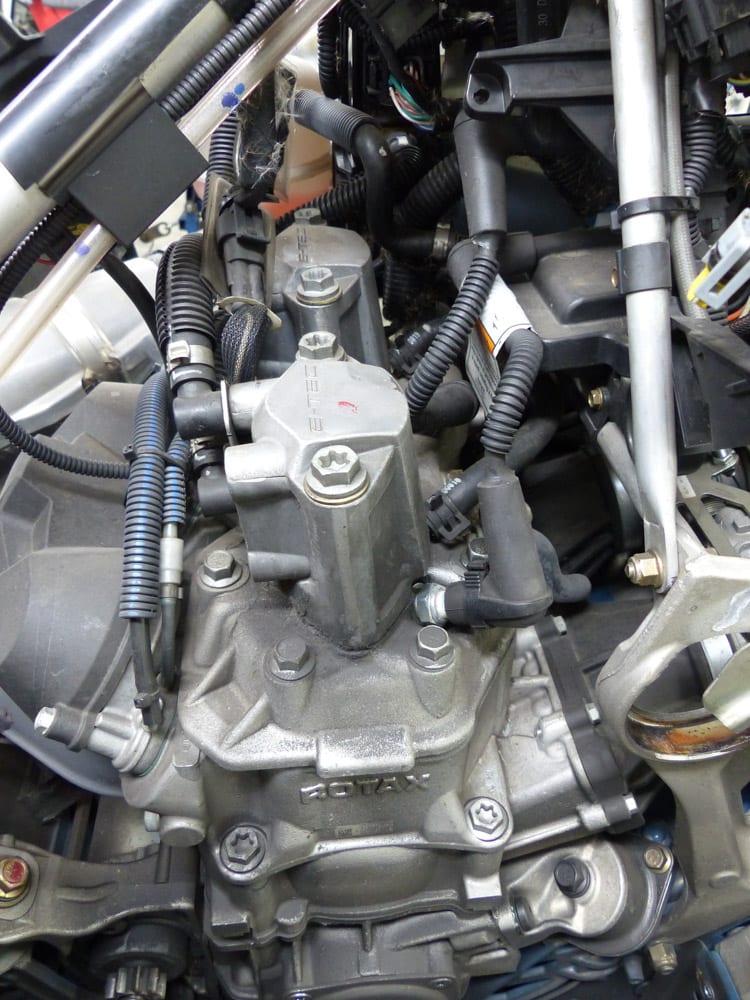

Let’s take the Skidoo “E-tec” engine as an example. The injector control module will wait until the engine piston position is below the exhaust window before injecting fuel. This eliminates the waste of fuel to the exhaust. The type of injector used by Skidoo reminds me of those used in diesel engines. This mechanism is a sort of electromechanical pump, which explains the imposing size of each injector positioned at the top of the engine. This injection, under high pressure, can reach up to 650 PSI with some manufacturers, which favors a more homogeneous vaporization of the gasoline.

The essence

The fuel and its supply must remain optimal. It is very important to use the gasoline required by the manufacturer of your snowmobile. The octane level required by the manufacturer of your snowmobile is not to be taken lightly. Its role is to prevent auto-ignition. This condition occurs when the gasoline ignites during the engine’s compression cycle before the spark plug even ignites. This is very damaging to the engine and can lead to costly repairs.

There are other criteria about the gasoline to consider. Gasoline degrades very quickly. Here’s why: for greenhouse gas reduction reasons, Canada, through its Renewable Fuels Regulations, has imposed, since September 1, 2010, a 5% average renewable fuel content based on the volume of gasoline. In addition, the same regulations define high-renewable-content fuel as a liquid petroleum fuel with a renewable fuel content of more than 10%, but no more than 85% for gasoline.

In other words, here we are talking about ethanol-blended gasoline. E10 for 10% ethanol, E15 for 15%, do you understand? Up to E85! The vehicles designed for these fuels are called flex fuel. These vehicles have a sensor that measures the concentration of ethanol in the gasoline. An adapted map management and materials that have properties adapted to resist ethanol are used. In the automobile, a maximum mixture of 10% E10 ethanol is tolerable for engine management without being Flex fuel.

In the world of motorized recreation, ethanol is very bad for them. They are not adapted to the corrosive effect of this fuel. There is a possible risk of premature degradation of the components of the fuel system. In addition, this gasoline has the bad quality of being soluble in water and acts as a sponge for it. Avoid gasoline cans that sit in the shed for months at a time. Get ethanol-free gasoline. It’s not easy to do, but some oil companies offer it in the supreme.

Although carburetors are easily and inexpensively modified, making them a favorite among engine enthusiasts, they are still a temperamental technology. Carburetors often need to be cleaned for proper operation. In addition, carburetors have the annoying tendency to freeze in winter, which is risky for the engine. Starting the engine requires the chaotic management of the choke. The carburetors do not have the capacity to automatically adapt to changes in altitude and temperature, and they emit a strong exhaust smell.

On newer snowmobiles, regardless of the type of fuel injection, you no longer have to deal with the damn choke lever. Everything is wonderfully done electronically. Much less maintenance, low exhaust odor and greatly improved fuel economy. However, this technology requires specialized equipment to operate.

Fueling your snowmobile – Conclusion

With the exception of a few cases, fuel-injected snowmobiles hold the first place in the choice of snowmobilers. It seems that only 3% of them prefer carbureted snowmobiles. It is not surprising to arrive at this result when one realizes the performance combined with the simplicity of operation of a fuel-injected snowmobile.